Düsseldorf

Bonner Str. 367-371

40589 Düsseldorf

Phone:+49 211 515 81 70

Fax:+49 211 515 81 728

Email: info@trade-world-one.de

Vienna

Rathausstrasse 21/12

1010 Vienna

Phone: +43 664 171 89 69

Email: kontakt@trade-world-one.at

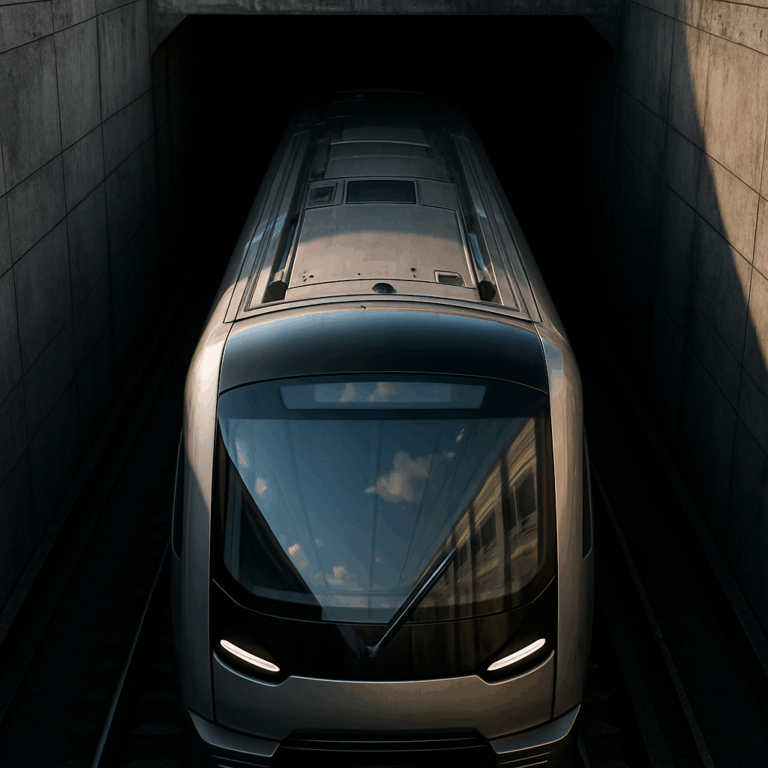

Windshield Wipers for Rail Vehicles: More Than Just a Wipe – Technology, Procurement, and Lifecycle Management

In the complex world of transportation technology, where digital control systems, propulsion technology, and bogie components dominate the technological discourse, the train windshield wiper system is often overlooked. It is perceived as a common, almost trivial component. However, this perception is deceptive and poses significant risks to the operational safety and availability of rail vehicles. At Trade World One, where our industrial DNA roots us deeply in the processes of transport operators and manufacturers, we view the wiper system not as an off-the-shelf product, but as a highly specialized, safety-critical mechatronic system. Its failure can immobilize a vehicle, jeopardize schedules, and, in extreme cases, compromise the safety of passengers and crew.

Do you have any questions? Feel free to contact us at any time.

» To the contact pageThe demands on such a system are immense: it must function reliably at speeds exceeding 200 km/h, withstand the pressure wave impact of entering tunnels, perform in ice and snow as well as in heavy rain, and remain maintainable with a secure supply of spare parts over a service life of several decades. This technical article explores the engineering depths, the regulatory framework, and the significant challenges in the procurement and lifecycle management of windshield wipers for rail vehicles.We demonstrate why a profound technical understanding and a proactive, solution-oriented procurement strategy are essential to secure operational readiness today and in the future.

Requirements for Windshield Wipers on Trains: Standards and Operating Conditions

The primary function of a windshield wiper for rail vehicles is to ensure a clear view for the train driver under all weather conditions. This requirement is anchored in numerous standards, first and foremost in the TSI LOC & PAS (Technical Specifications for Interoperability for Locomotives and Passenger Rolling Stock) and in the UIC Leaflets.

Illustrative Example:

If the wiper system fails during a heavy thunderstorm or when entering a tunnel, the train driver has severely limited visibility – a single wiper failure can lead to a complete standstill at short notice and, in extreme cases, to safety risks for passengers and crew.

But the normative requirements are only the baseline. The real operating conditions define the true challenges for every rail vehicle wiper:

- Aerodynamic Loads: With increasing speed, significant forces act on the wiper arm and blade. The design must compensate for this aerodynamic lift, often through integrated spoilers.

- Mechanical Stresses: Vibrations, shocks, and the abrupt pressure wave impact during tunnel passages constitute a massive mechanical load that the entire system must withstand.

- Climatic Extremes: The system must function reliably from -40 °C to +70 °C. This affects the viscosity of the gearbox grease, the elasticity of the wiper blade'srubber compound, and the electronics. Icing often requires heated parking positions or heated wiper arms.

- Chemical Resistance: Cleaning fluids and environmental factors require corrosion-resistant materials such as stainless steel and chemically inert plastics.

These cumulative stresses make it clear that a rail wiper system is a distinct, highly robust engineering solution.

Field Test as Proof:

The practical relevance of such requirements is demonstrated, for example, by the sludge test conducted by BROT Technologies: at 250 km/h, the wiper system was tested under extreme dirt and weather conditions – with the result that visibility was reliably maintained even under these circumstances. Such tests significantly exceed common standards and prove the high reliability of modern systems.

Anatomy of the Rail Vehicle Wiper: The Components in Detail

A train windshield wiper system is an assembly of precisely coordinated components. As a technical procurement partner, our focus is on understanding each of these components to deliver perfectly fitting and durable solutions.

The Wiper Motor: The Heart of the System

The wiper motor is the power source, typically a high-performance DC motor (24V, 72V, or 110V). The choice between wear-prone brushed motors and durable but more expensive brushless (BLDC) motors is crucial for spare parts procurement in the rail sector and for modernizations.

The Gearbox: Power Converter and Pacemaker

The worm or spur gear drive converts the motor's speed into the high torque required at the wiper arm. The quality of the gearing and the lifetime lubrication are critical features here.

The Wiper Arm (Pantograph): Leverage with Precision

The wiper arm transmits the force and provides the necessary contact pressure. For large windshields, pantograph systems are used almost exclusively. This design guides the wiper blade perpendicular to the glass, ensuring a uniform cleaning action. Integrated springs generate the specified contact pressure (often 10-25 N).

The Wiper Blade: The Critical Interface with the Glass

The wiper blade is the actual wear part. The rubber compound (e.g., natural rubber or synthetic EPDM) and graphite-based coatings are crucial for a low-friction, clean wiping performance. Procuring the exactly matching wiper blade is a typical challenge for wipers in the rail transport sector.

The Control and Washing System: Intelligent Peripherals

Modern railcar wiper systems are often integrated into the Train Control and Management System (TCMS/MVB/CAN-Bus). This enables intelligent functions such as speed-dependent intermittent wiping. The washing system with heated nozzles is an integral part of the safety function.

Procurement and Lifecycle Management for Wiper Systems: The Role of the Specialist

Technical complexity is only one side of the coin. For operators, the real hurdles lie in procurement and supply security, especially in the maintenance of rail vehicles.

Obsolescence Management: The Nightmare of Every Maintenance Department

Rail vehicles have a service life of over 30 years. The manufacturers of the original windshield wipers often no longer exist. A defective locomotive wiper or its motor can thus take a vehicle out of service. This is where our engineering team analyzes a defective legacy part and, based on a sample, has a functionally compatible spare part manufactured – including all tests required for re-approval.

Documentation and Certification: The Invisible Hurdle

Every component requires complete documentation. If this is missing, a part cannot be legally installed. We ensure that every part we supply – whether a wiper motor or a wiper arm – complies with the regulatory requirements of the rail sector.

Customization and Small Batches: Every Train is Different

There is no “one-size-fits-all” solution for train windshield wipers. Specific lengths or adapters are often required. We work with flexible manufacturers to procure even small batches to exact customer specifications.

Logistics and Availability: When Downtime is Not an Option

A failed train windshield wiper can take a vehicle out of service for days. Our 1,500 sqm warehouse and a proactive stocking strategy for critical components like the rail wiper transform a potential multi-day outage into a matter of hours.

The Future of Wiper Systems for Rail: Intelligence and Predictive Maintenance

- Predictive Maintenance: The analysis of motor data allows for predictive maintenance. The system proactively reports an impending maintenance need before a failure occurs.

- System Integration and Sensor Fusion: Future systems will be even more closely networked with cameras and weather services to make wiper control more intelligent.

- Material Innovations: Research into new materials for wiper blades and hydrophobic coatings for windshields will further extend the overall system's service life.

Conclusion: Partnership as the Key to Success

The windshield wiper for rail vehicles is a prime example of how a seemingly simple component can reveal enormous technical and logistical complexity. Its reliable operation is the result of a precise interplay of mechanics, electronics, and material science.

For operators, the key to success lies not in purchasing the cheapest individual part, but in partnering with a specialist who understands the entire process chain for train windshield wipers. A partner who masters the technical challenges, knows the global markets to find solutions even for obsolescence management, and ensures maximum fleet availability through intelligent logistics.

This profound industrial experience, this understanding of quality and supply chains, is the DNA of Trade World One. We don’t deliver off-the-shelf products – we deliver tested, documented, and precision-fit solutions. Because we know: when it comes to the safety and operational readiness of your vehicles, absolute reliability is non-negotiable.

Components. Solutions. Availability. We are your technical implementation partner. Challenge us with your requirements.

Sources

- Scheibenwischsysteme für Züge – Knorr-Bremse: Umfassende Informationen zu bahntauglichen Scheibenwisch- und Waschsystemen für Schienenfahrzeuge, deren Wartungszyklen und Anwendungen von Straßenbahn bis Hochgeschwindigkeitszug.

- Fensterarten für Schienenfahrzeuge – Kunststofftechnik Hennigsdorf: Details zu verschiedenen Fenstersystemen und deren Sicherheits- und Komforteigenschaften für den Einsatz in Schienenfahrzeugen.

- Scheibenwischer und weitere Komponenten für Schienenfahrzeuge – WerkZeug Technik: Überblick über Produkte und Systeme für Schienenfahrzeuge inklusive Scheibenwischer und deren Rolle im Bahnbereich.

- Der Eisenbahn-Fensterwischer – BROT Technologies: Technische Merkmale, Einsatzbereiche und Vorteile von speziellen Scheibenwischern für Züge, auch unter extremen Bedingungen und bei Hochgeschwindigkeiten.

- Kompressoren für Schienenfahrzeuge – Atlas Copco: Erklärung der pneumatischen Anforderungen bei Schienenfahrzeugen, einschließlich der Nutzung von Druckluft für Scheibenwischer.

- Zugangslösungen für Wartung von Scheibenwischern – ZARGES: Informationen zu sicheren und ergonomischen Arbeitsbühnen und Zugangslösungen für die Wartung von Frontscheiben und Scheibenwischern bei Schienenfahrzeugen.

- Forschung und Entwicklung an Schienenfahrzeug-Technik – Railway Technology: Wissenschaftliche Einblicke in technische Innovationen bezüglich Schienenfahrzeugkomponenten, einschließlich Scheibenwischer.

- Forschungsartikel zu Scheibenwischern im Schienenverkehr – SAGE Journals: Wissenschaftliche Studien zur Optimierung der Scheibenwischsysteme unter Berücksichtigung von Aerodynamik und Wetterbedingungen.

- Windshield Wipers for Trains – ResearchGate: Technische Publikation über Konstruktion und Herausforderungen bei Wischersystemen für Schienenfahrzeuge.

- Analyse der Wischblatt-Performance bei Schienenfahrzeugen – ResearchGate: Betrachtung von Materialeigenschaften und Leistung von Scheibenwischblättern in der Bahnindustrie.

Do you have any questions? Feel free to contact us at any time.

» To the contact page