Düsseldorf

Bonner Str. 367-371

40589 Düsseldorf

Phone:+49 211 515 81 70

Fax:+49 211 515 81 728

Email: info@trade-world-one.de

Vienna

Rathausstrasse 21/12

1010 Vienna

Phone: +43 664 171 89 69

Email: kontakt@trade-world-one.at

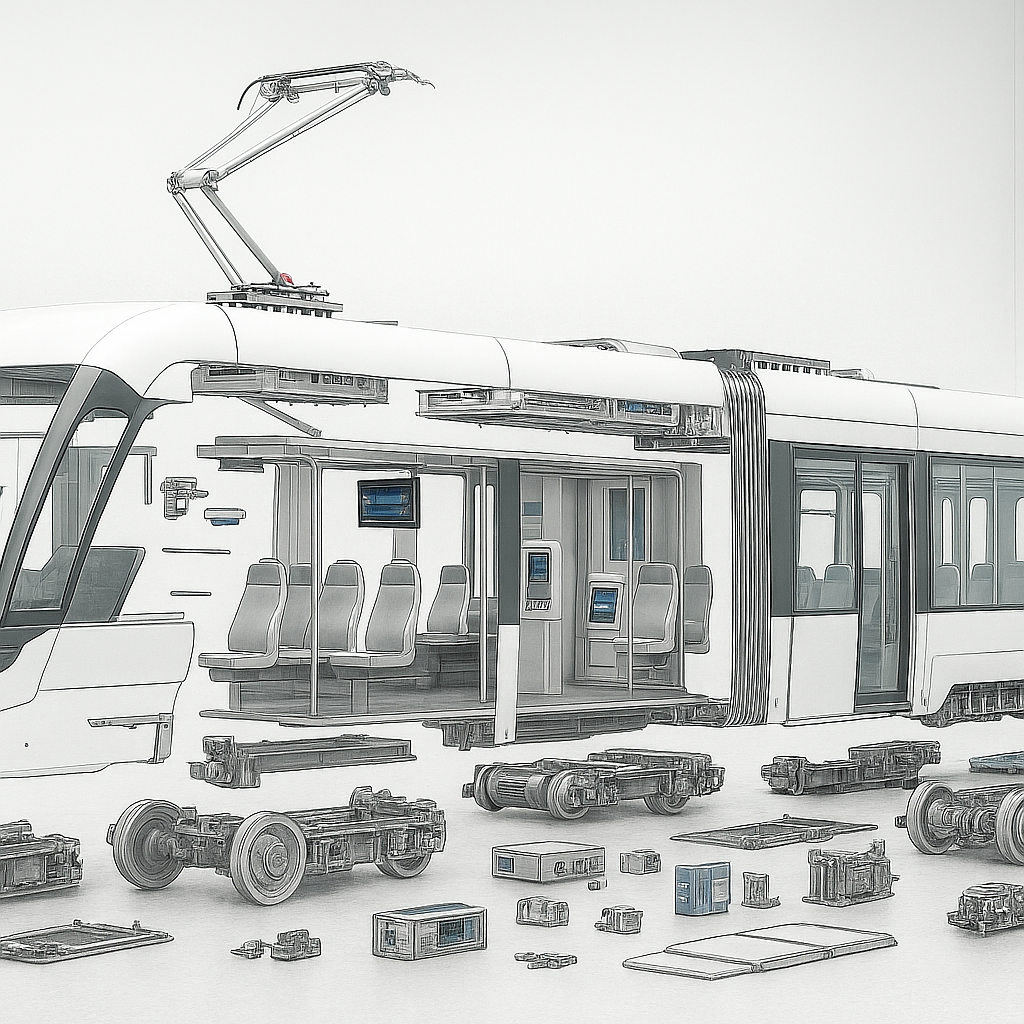

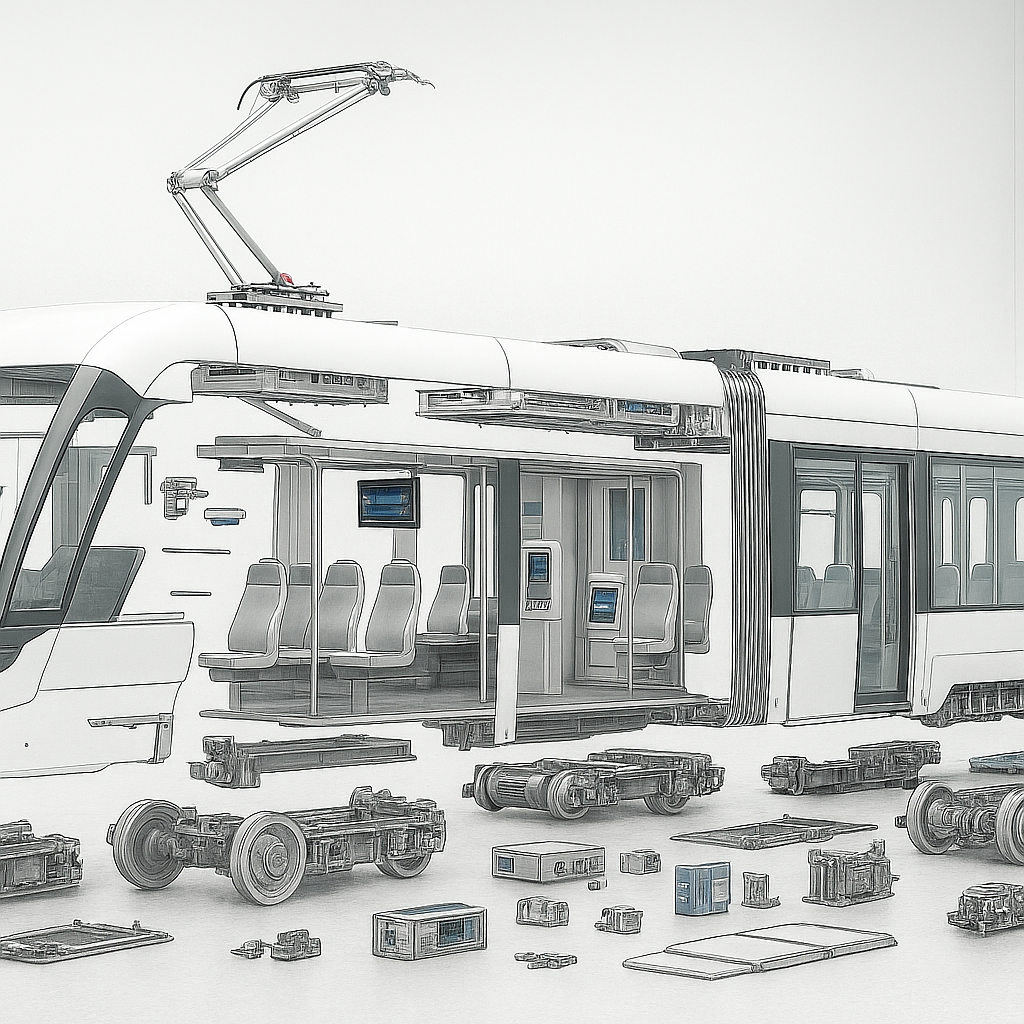

Spare Parts for Trams: Strategic Management for Urban Mobility

As a technical procurement partner with deeply rooted industrial DNA, we at Trade World One experience the complex challenges facing public transport operators and municipal utilities on a daily basis. Trams, light rail, and metro systems are the long-life backbone of public transport. Their operational lifecycles of 30, 40, or even more years stand in sharp contrast to the fast-paced nature of technological developments and global supply chains.

Do you have any questions? Feel free to contact us at any time.

» To the contact pageThe demand extends far beyond the classic replacement of individual components. The day-to-day operations of public transport operators involve highly safety-critical systems such as chassis, propulsion, and brakes, as well as bodywork, glazing & exterior components, mechanical components & manufacturing processes, interior & passenger systems, profiles, elastomers & plastics, and even areas like vehicle electronics and environmental & plant technology. These systems are technically interconnected and determine the safety, comfort, and availability of fleets.

Ensuring operational readiness through precision-fit spare parts for trams is therefore not a matter of simply replacing components. It is a strategic task that requires deep technical understanding, forward-looking planning, and robust, agile procurement logistics for the rail sector. This article highlights the crucial aspects of managing these safety-critical components—from the outer shell to power electronics—and demonstrates how supply chain resilience can be established. We don’t deliver off-the-shelf products—we deliver solutions for your public transport spare part requirements.

The Challenge: Why Tram Spare Parts Are a Discipline in Their Own Right

The complexity in managing tram spare parts arises from a unique convergence of factors. Unlike the automotive industry, the rail vehicle market is characterized by a heterogeneous fleet structure. A public transport operator often maintains vehicles from multiple generations. Each series has its own specifics and wear patterns, which complicates the procurement of replacement parts for light rail vehicles.

The demand in these fleets covers, among other things, wheelsets and wheel tires, wheelset bearings and bearing housings, propulsion and braking systems, traction motors and gearboxes, nose-suspended drives and hollow-shaft drives, brake linkages and brake cylinders, power electronics such as traction converters/inverters, as well as vehicle electronics and control units.

ENGLISCH: The complexity in managing tram spare parts arises from a unique convergence of factors. Unlike the automotive industry, the rail vehicle market is characterized by a heterogeneous fleet structure. A public transport operator often maintains vehicles from multiple generations. Each series has its own specifics and wear patterns, which complicates the procurement of replacement parts for light rail vehicles.

The longevity of the vehicles is both a blessing and a curse. While many mechanical structures are designed to last for decades—such as bogie parts, load-bearing castings, or interior modules—electronic assemblies have a significantly shorter lifecycle. This leads to the phenomenon of obsolescence: components for light rail vehicles are no longer available because the OEM has ceased production. This affects, for example, vehicle electronics, control units, power electronics/converters, and door control systems, but also specific glazing, molded GRP parts for the outer shell, or profiles with legacy material approvals. Here, structured obsolescence management becomes a core task for public transport operators.

Every component—from the smallest relay to the front apron—must meet certified quality standards and have complete technical documentation. A failure jeopardizes operational safety. This complex situation demands a partner who understands the language of technology—precise, detail-oriented, and solution-driven.

Critical Chassis Components: Reliable Spare Parts for Running Gear and Bogies

The running gear is the mechanical heart of every tram. The components installed here are permanently under high load. For public transport operators, the areas of demand include, among others:

- Wheelsets and wheel tires as the direct interface to the rail, with tight tolerance specifications

- Wheelset bearings and bearing housings, the failure of which typically leads to an immediate vehicle standstill

- Suspension systems such as coil springs, rubber-to-metal elements, and air springs, which exhibit material fatigue over the years and are often no longer available according to the original drawings

Propulsion and Braking: Function-Critical Systems

Propulsion and braking systems are safety-relevant and operationally critical. For operators, this typically involves:

- Traction motors and gearboxes

- Nose-suspended drives and hollow-shaft drives

- Wear parts such as carbon brushes, bearings, and seals

- Brake linkages and brake cylinders as central elements of the mechanical brake

- Braking resistors and braking units in combination with the electric power train

- Power electronics and converter systems (e.g., traction converters/inverters)

These systems combine heavy-duty mechanics with complex power electronics. Failures in these assemblies have a direct impact on safety, deceleration performance, and tractive effort – and thus on the daily operational readiness of the fleet.

The Achilles' Heel of Modern Fleets: Obsolescence Management in Vehicle Electronics

The pressure is most evident in the field of vehicle electronics. Control units, door control systems, air conditioning controllers, traction control systems, and propulsion inverters are based on electronic platforms with very short market cycles.

When such systems are no longer available, there is often acute pressure to act. Typical situations for public transport operators include, for example:

- Electronics fail, but no standard spare part is available anymore

- Printed circuit boards are repairable, but current bills of materials or layout data are no longer available

- The original function (Form-Fit-Function) must be maintained, even though component geometries, software versions, or safety approvals are outdated

- Passenger and interior systems (e.g., LED-based destination signs, interior information displays) are based on electronics that can no longer be procured

This makes vehicle electronics one of the biggest risk factors for the remaining service life of a vehicle—long before its mechanical structure is exhausted.

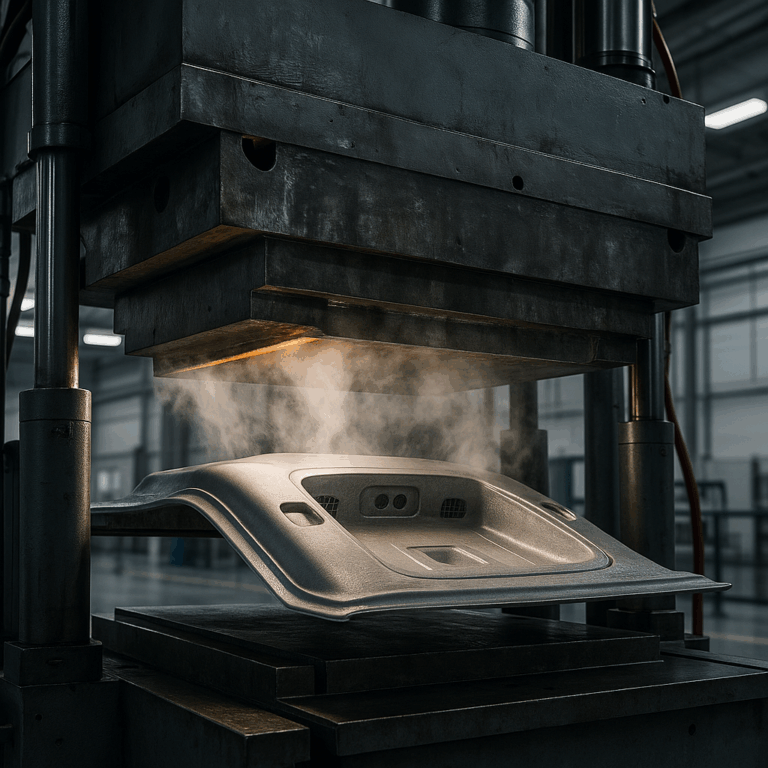

Bodywork, Glazing & Exterior Components

In parallel to the "underfloor" systems, a second, often underestimated supply field emerges: the vehicle's outer shell and glazed areas. Here, public transport operators have an ongoing demand for components that are functionally critical to safety, such as:

- Front and rear windshields in Laminated Safety Glass (VSG) quality

- Side windows in Toughened Safety Glass (ESG) quality, available curved or heated

- Rail windows, bus windows, hinged and sliding windows

- Glass-fiber reinforced plastic (GRP), CFRP/AFRP components, exterior panels, side skirts

- Formed steel and aluminum parts with specific corrosion and surface requirements

- Components meeting fire protection requirements according to DIN EN 45545

These components are visually prominent but are technically far more than just "cosmetics": they protect the structure, are crash-relevant, ensure visibility, and are partially subject to approval.

Interior & Passenger Systems

The interior also presents a continuous demand for components that ensure safety, comfort, and passenger information. These typically include:

- Passenger seats and seat frames

- Grab rails and mounting parts

- Luggage rack covers and securing nets

- Partition and luggage nets in various designs

- LED circuit boards for opto-electronic displays and destination signs

These components are subject to strict requirements regarding fire protection, ergonomics, vandalism resistance, and long-term durability.

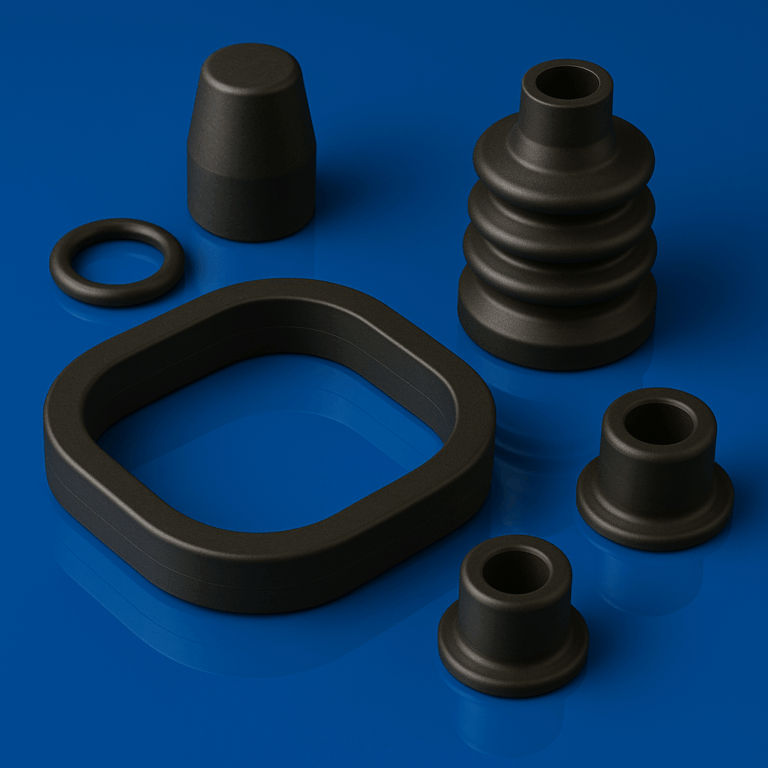

Profiles, Elastomers & Plastics

In tram operations, profiles, elastomers, and plastics also play a central role:

- Aluminum profiles (extruded profiles), anodized, powder-coated, or further machined

- Rubber profiles, sealing profiles, molded rubber and plastic parts, incl. corner vulcanization

- Rubber-to-metal elements

- PU foam parts with flame-retardant properties

- Plastic injection molded parts with functional surfaces

- Hose and sealing systems

These components are often vehicle-specific and therefore cannot be easily replaced with standard components.

Quality and Certification: The Foundation for Safety-Critical Components

In a safety-critical environment, the quality of spare parts for trams is an absolute imperative. Our ISO 9001 certification is merely the visible framework. Every element of the supply chain is quality-assured—from material analysis and production monitoring to non-destructive testing (NDT) and documented inspection reports.

This applies equally to load-bearing castings, glazed exterior components, interior parts with fire protection requirements, profiles, and elastomers.

Strategic Procurement Logistics: Securing Supply for Public Transport Operators

Our 1,500 sqm warehouse serves to stock critical operational components and secure their availability. This reduces the capital tied up by operators while simultaneously supporting the fleet's operational readiness. In addition, we offer:

- Consignment stock directly at the customer's site, stocked with essential wear and maintenance components

- Kitting, which is the provision of complete part sets for planned interventions such as a bogie overhaul or an interior refurbishment

- Demand and consumption analyses for the early procurement of components before they become critical

The DNA of Trade World One is the technical understanding of the interface between demand, obsolescence risks, and supply security. This understanding covers the central areas of demand for public transport operators, from chassis and bogie systems, through propulsion and braking systems, to vehicle electronics—all areas where failures directly jeopardize fleet operational readiness and where product discontinuations, lack of spare part availability, and regulatory requirements frequently converge.

Based on this foundation, Trade World One's core competence lies in the reliable supply of components in the areas of bodywork, glazing & exterior components, interior & passenger systems, as well as profiles, elastomers & plastics—with the goal of keeping these vehicle- and safety-critical assemblies available throughout their lifecycle in a standard-compliant, verifiable, and robust manner.

Conclusion: Partnership is the Key to Rail Vehicle Maintenance

Securing the operational readiness of fleets by reliably meeting the demand for system-critical assemblies is a marathon, not a sprint. It demands technical understanding, market knowledge, and the ability to ensure supply security even when individual components are discontinued or not readily available.

The DNA of Trade World One lies precisely in this understanding of demand, risk, and the duty to supply—and in the ability to translate this insight into robust material availability for the relevant assembly groups. This creates the foundation for resilient, future-proof urban mobility.

Sources

- Diplomarbeit: Güterstraßenbahnen als alternative Transportmittel

- Ersatzteile für Straßenbahn und Vollbahn

- Branchenanalyse Bahnindustrie

- Dissertation: Komplexitätsmanagement mittels Optimierung

- Schlussbericht: Studie für urbane Seilbahnen im ÖPNV

- Smart Mobility

- Neue Strategien in der Instandhaltung von Fahrzeugen des SPNV

- Deutsche Bahn will Züge und Ersatzteile in China kaufen

- Analyse der Marktdynamik im Verkehrswesen

- Ein Beitrag zur Optimierung der Informationslogistik im Ersatzteilwesen

Do you have any questions? Feel free to contact us at any time.

» To the contact page