Düsseldorf

Bonner Str. 367-371

40589 Düsseldorf

Phone:+49 211 515 81 70

Fax:+49 211 515 81 728

Email: info@trade-world-one.de

Vienna

Rathausstrasse 21/12

1010 Vienna

Phone: +43 664 171 89 69

Email: kontakt@trade-world-one.at

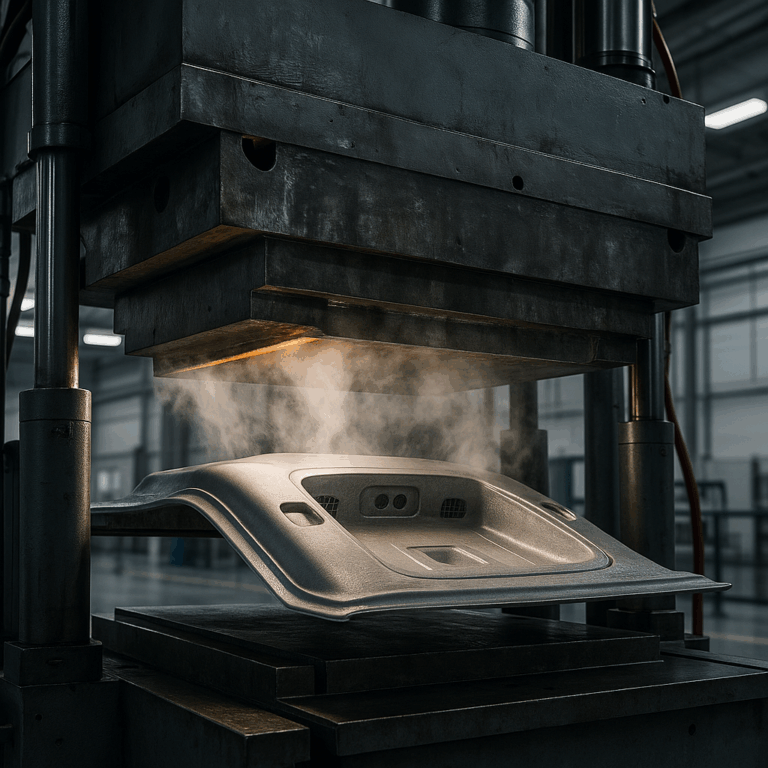

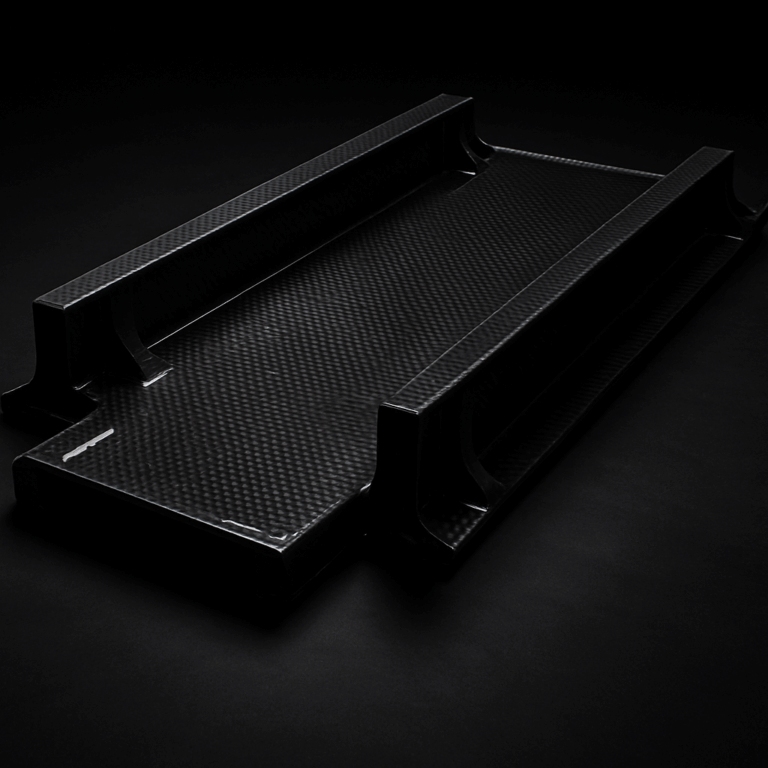

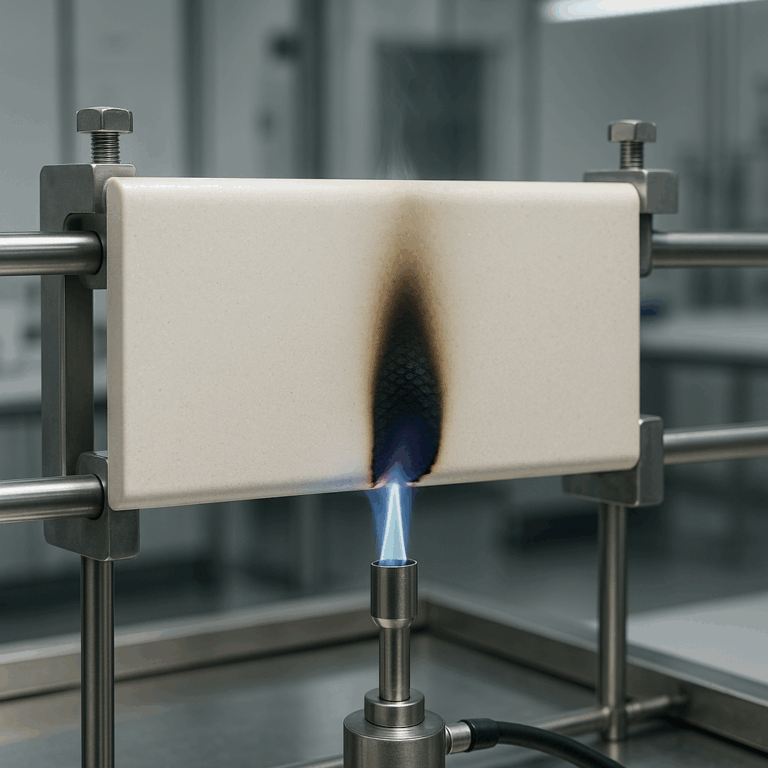

Cargo Net Covers

Cargo net covers offer reliable protection and secure fastening for your luggage—ideal for industry, transport, and professional use. Discover high-quality, durable solutions that optimally secure your cargo and make your daily work easier. Find the right cargo net covers now and increase safety!